Reliable and Energy Efficient Pool Heaters Built to Last!

A properly heated swimming pool creates constant comfort and extends the swimming season indefinitely. When it comes to energy efficiency, reliability, and durability, Hayward H-Series heaters are certainly among the best. H-Series heaters from are reliable and hydraulically efficient pool heaters that can quickly heat up pool water so that you can enjoy peace of mind and maximum comfort when luxuriating in the pool.

Here we will take a detailed look at the COMPLETE H-Series range of gas pool heaters, their unique features, and the type of pool that they would suit.

Hayward H-Series Pool Heaters: Quick Overview

Everything in the Universal Hayward H-Series range of is built using high quality materials and parts - so you can expect long life and durability. They are easy to install and operate. A unique feature of the H-Series is one element that gives it unsurpassed heating efficiency, namely the commercial grade cupro nickel heat exchanger.

The superior build quality of this component prevents damage arising from pool water chemistry thereby creating dependability and long lasting value at an affordable cost.

A Fire sealed combustion chamber maximizes energy efficiency and make sure no heat leakages occurs thereby maximizing the heat transfer to your pool.

Factory fitted left or right side electric water and gas connections allow easy installation and flexibility. A simple yet modern appearance combined front panel only access for service and installation makes any H-series heater compatible with existing systems or new configurations.

Features and Functionality

- Flexibility

- Dual Voltage – Hayward H-Series pool heaters are adaptable to both 100V and 220V.

- Universal Wiring– Installation is simplified due to high and low voltage connections that are conveniently located at either side of the junction boxes.

- Environmental Friendly

- Low nitrogen oxides (NO and NO2) Emission – All H-Series heaters are environmentally efficient, and comply with air quality emission standards.

- High Value and Performance

- Superior Hydraulic Performance – commercial grade hydraulic performance saves energy costs by reducing pump runtime requirements.

- Standard Cupro Nickel Heat Exchanger – offers erosion protection and corrosion resistance. This is perfect for modern salt based chlorination systems.

- Digital LED Control Panel – A front access digital control panel makes it easier to monitor heater performance, maintain water temperature, and diagnose the system.

The Winning Combination

The Universal H-Series represents the winning combination of rugged design and efficient functionality which makes it an intelligent choice for modern swimming pools. Hayward's heating systems follow an economical approach to energy consumption which means they are light years ahead in efficiency compared to gas heaters of even 5 years ago.

Exceptional hydraulic performance will save your energy bill by reducing pump runtime, with the added bonus of warming your pool or spa in less time. You can swim in comfort and stretch your pool season without worrying about excessive energy bills.

All H-Series heaters come with an LED control panel. This front panel makes it easy to use and convenient to monitor heat performance. The ignition system is very dependable and kicks in with one push of a button.

What’s best about H-Series heaters is that the air is constantly moved through the combustion chamber due to a forced draft system. This eliminates all types of external weather variables that affect performance such as wind, which eliminates the need for installing a high-wind stack. As a result the heater performs efficiently resulting in great cost savings.

Cupro nickel heat exchangers and polymer headers makes it possible for these gas heaters to withstand high flow rates, aggressive pH levels, and saltwater chlorination. In addition, installation is easy due to the combination of universal-fit flexibility and left or right side gas, water and electric fittings.

Other notable features include the insulated fire tile combustion chambers, stainless steel burners, and corrosion resistant heat exchangers. The combination of these features allows the heater to deliver exceptional performance from every BTU. It is suitable for both indoor and outdoor pools and spas. However, you need to install a vent adaptor kit to make it compatible for indoor installations.

Selecting the Best Hayward H Series Pool Heater

1. Hayward Universal H-Series Pool and Spa Heater - Model#: H150FDN

H150FDN - 150k BTU - Electric/Natural Gas

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 150k BTU heat input suitable for 450 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and natural gas

Description

The Hayward Universal H150FDN is a high quality pool and spa heater that runs using a combination of electric and natural gas. This pool heater provides a modest 150,000 BTU of heat. It is suitable for swimming pools having surface areas of up to 450 square foot. This water heater can easily raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in about an hour.

2. Hayward Universal H-Series Pool and Spa Heater - Model# H150FDP

H150FDP - 150k BTU Electric/Propane

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 150k BTU heat input suitable for 450 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and propane gas

Description

The Hayward Universal H150FDP Pool and Spa Heater runs on electricity and propane fuel. This pool heater divulges 150,000 BTU of heat, and is suitable for swimming pools having surface areas of up to 450 square foot. The water heater can also raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in about an hour.

3. Hayward Universal H-Series Pool and Spa Heater - Model# H200FDN

H200FDN - 200k BTU - Electric/Natural Gas

H200FDN - 200k BTU - Electric/Natural Gas

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 200k BTU heat input suitable for 600 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and natural gas

Hayward Universal H-Series Pool and Spa Heater - 200k BTU - Electric/Natural Gas - $1,665.00

from: POOL CENTER

Description

The Hayward Universal H200FDN is a quality pool and spa heater that runs using a combination of electric and natural gas. This pool heater provides 200,000 BTU of heat. It is appropriate for swimming pools having surface areas of up to 600 square foot. The water heater can easily raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in about 47 minutes.

4. Hayward Universal H-Series Pool and Spa Heater - Model#H200FDP

H200FDP - 200k BTU - Electric/Propane

H200FDP - 200k BTU - Electric/Propane

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 200k BTU heat input suitable for 600 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and propane gas

Hayward Universal H-Series Pool and Spa Heater - 200k BTU - Electric/Propane - $1,665.00

from: POOL CENTER

Description

The Hayward Universal H200FDP Pool and Spa Heater runs on electricity and propane fuel. This gas pool heater provides also provides 200,000 BTU of heat, and is suitable for swimming pools having a surface area of up to 600 square foot. This heater can raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in 47 minutes.

5. Hayward Universal H-Series Pool and Spa Heater - Model#H250FDN

H250FDN - 250k BTU - Electric/Natural Gas

H250FDN - 250k BTU - Electric/Natural Gas

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 250k BTU heat input suitable for 750 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and natural gas

Description

This Hayward Universal H250FDN Pool and Spa Heater is an energy efficient pool and spa heater that uses electric and natural gas power to heat the water. This gas heater provides 250,000 BTU of heat. It is fit for swimming pools having surface area of up to 750 square foot. The water heater can easily raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in about 36 minutes.

6. Hayward Universal H-Series Pool and Spa Heater - Model#H250FDP

H250FDP - 250k BTU - Electric/Propane

H250FDP - 250k BTU - Electric/Propane

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 250k BTU heat input suitable for 750 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and propane gas

Hayward Universal H-Series Pool and Spa Heater - 250k BTU - Electric/Propane - $1,930.00

from: POOL CENTER

Description

The Hayward Universal Heater H250FDP Pool and Spa uses electricity and propane fuel to heat the water. This pool heater transfers 250,000 BTU of heat, and is fitting for swimming pools with a surface area of up to 750 square foot. This pool heater can raise the temperature of 1,000 gallon pools to 15 degrees Fahrenheit in just 36 minutes.

7. Hayward Universal H-Series Pool and Spa Heater – Model#H350FDN

H350FDN - 350k BTU - Electric/Natural Gas

H350FDN - 350k BTU - Electric/Natural Gas

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 350k BTU heat input suitable for 1,050 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and natural gas

Hayward Universal H-Series Pool and Spa Heater - 350k BTU - Electric/Natural Gas - $2,089.00

from: POOL CENTER

Description

The Hayward Universal H350FDN is a reliable pool and spa heater that makes use of electricity and natural gas to heat the water. This natural gas pool heater provides 350,000 BTU of heat. It is appropriate for swimming pools that have surface area of up to 1,050 square foot. For both pools and spa this heater can easily raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in about 27 minutes thereby saving you large amounts in energy bills as compared to traditional pool heaters.

8. Hayward Universal H-Series Pool and Spa Heater – Model#H350FDP

H350FDP - 350k BTU - Electric/Propane

H350FDP - 350k BTU - Electric/Propane

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 350k BTU heat input suitable for 1,050 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and propane gas

Hayward Universal H-Series Pool and Spa Heater - 350k BTU - Electric/Propane - $2,089.00

from: POOL CENTER

Description

The Hayward Universal H350FDP Pool and Spa Heater uses electricity and propane fuel to run. This pool heater also provides 350,000 BTU of heat, and is suitable for swimming pools having surface area of up to 1,050 square foot. This pool and spa water heater can raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in just 27 minutes.

9. Hayward Universal H-Series Pool and Spa Heater – Model#H400FDN

H400FDN - 400k BTU - Electric/Natural Gas

H400FDN - 400k BTU - Electric/Natural Gas

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 400k BTU heat input suitable for 1,200 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and natural gas

Description

The Hayward Universal H400FDN Pool and Spa Heater is a high quality product that utilizes electricity and natural gas to heat the water. This powerful pool heater provides 400,000 BTU of heat which is appropriate for large swimming pools with a surface area of up to 1,200 square foot. For pools and spas it can easily raise the temperature of 1,000 gallons pool water to 15 degrees Fahrenheit in about 24 minutes thus lowering the pump runtime and subsequently energy bills.

10. Hayward Universal H-Series Pool and Spa Heater – Model#H400FDP

H400FDP - 400k BTU - Electric/Propane

H400FDP - 400k BTU - Electric/Propane

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 400k BTU heat input suitable for 1,200 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and propane gas

Description

The Hayward Universal H400FDP Pool and Spa Heater runs on electricity and propane fuel to heat the water. This pool heater also provides 400,000 BTU of heat, and is suitable for swimming pools having surface area of up to 1,200 square foot. This pool and spa water heater can raise the temperature of 1,000 gallons of pool water to 15 degrees Fahrenheit in just 24 minutes.

11. Hayward Universal H-Series 500 K BTU Pool Heater – Model#H500FDN

H500FDN - 500k BTU - Electric/Natural Gas

H500FDN - 500k BTU - Electric/Natural Gas

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 500k BTU heat input suitable for 1,600 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and natural gas

Hayward Universal H-Series Pool and Spa Heater - 500k BTU - Electric/Natural Gas - $2,568.00

from: POOL CENTER

Description

The Hayward Universal H500FDN is an electricity and natural gas pool and spa heater that provides up to 500,000 BTU for the fastest speed to heat performance. The heater is suitable for swimming pools having surface areas of up to 1,600 square foot. This monster heater can easily raise the temperature of 1,000 gallons of pool water to 15 degrees Fahrenheit in about 20 minutes.

12. Hayward Universal H-Series 500K BTU Pool Heater - Model#H500FDP

H500FDP - 500k BTU - Electric/Propane

H500FDP - 500k BTU - Electric/Propane

Salient Features

- Hayward universal design for easy installation

- Dual voltage (110v and 220v)

- Patented polymer header

- Digital led control panel

- Bypass lead ensures efficient hydraulic efficiency

- 500k BTU heat input suitable for 1,600 sq. foot swimming pool

- Superior reliability due to Standard Cupro Nickel Heat Exchanger

- Runs using electricity and propane gas

Hayward Universal H-Series Pool and Spa Heater - 500k BTU - Electric/Propane - $2,568.00

from: POOL CENTER

Description

The Hayward Universal H500FDP is a superior quality pool and spa heater that runs on a combination of electricity and propane fuel. It provides up to 500,000 BTU and is suitable for swimming pools having surface areas of up to 1,600 square foot. This pool and spa heater can raise the temperature of 1,000 gallons of pool water to 15 degrees Fahrenheit in only 20 minutes resulting in great savings in energy bills.

Getting The Most From Your Hayward H-Series Heater

Hayward H-Series heaters are suitable for use with pool and spa or hot tub water that is provided by municipal water distribution systems. Although they have a more robust CU (cupro nickel) heat exchanger you must pay attention to the limits.

It is not suitable for heating seawater with salt concentrations greater than 4000 PPM, mineral water, and other types of non-potable waters such as rainwater, quarry waters used for landscape irrigation, river, dam, or creek water, or recycled water.

In case you use automatic chlorinators and chemical feeders, you must install a chlorinator in the pool return line downstream from the heater at a lower elevation as compared to the heater.

In addition, a separate seal corrosion and resistant check valve should be installed between the chlorinator and the heater outlet. This is required to avoid sanitizers that are highly concentrated from back siphoning into the heater, which usually happens when the pump is shut off resulting in creation of a pressure differential.

Hayward CL200 In-Line Chlorinator - 9 lbs. Capacity - 5,000 to 45,000 Gallon Pools - $104.99

Lastly, a pressure relief valve that conforms to local building regulations may need to be installed under certain situations. It is recommended to install a ¾’’ pressure relief valve having a discharge capacity of more than or equal to the BTU rating of the heater. Moreover, the pressure relief rating of the heater should be less than the working pressure of the heater. Both this information is mentioned in the front access panel on the base pan.

The connection for the pressure relief valve is provided in the header of the heater. The pressure valve should be installed directly to the header in a horizontal position. Also, the discharge connection should face downward to the ground. You must connect a pipe that is of a similar size to the valve outlet and run it a safe discharge point. Avoid installing any restriction or shut-off in the discharge point.

A pressure relief value will prevent heater damage from deadheading and if your unit overheats.

Hayward H-Series Heating Process: An Overview

The Hayward H-Series works by comparing pool water temperature with the set point and the highest temperature limit. A heating cycle is initiated if the water temperature is 1 degree below the set point.

Next, the heater will check the open connections at the blower vacuum switch. If the connection is found open the heater powers on the igniter and the blower. It takes about 20 seconds for the igniter to begin heating the water. During this time the blower runs a pre-purge cycle to clean out the combustion chamber. In addition, the heater checks open connections at the vacuum switch.

A 4-second trial ignition begins once the Hayward heater has heated the water to a desired temperature. At this point the gas valve is opened and flame current is checked. After four seconds or after the flame is sensed, the igniter is turned off.

When the heater is in operation, the temperature limit switches, the blower vacuum switch, the vent pressure switch, the water temperature sensors, the water pressure switch, and the flame sensor are continuously monitored by the system to assure that the water is being heated without any problem.

After the water is heated to the desired temperature, and the call for heat ends, the gas valve is instantly de-energized by the system, and the flame is extinguished. At last a post-purge is initiated by the system that lasts for up to 30 seconds.

Close Monitoring

Hayward H-Series heaters take inputs through the keypad that are located on the front panel. When you change the mode from ‘STANDBY’ to ‘POOL’ or ‘SPA’, there will be a 10-second delay before the blower starts. The system performs an internal check to ensure that the switch connections are open before energizing the blower.

Also, note that it is usual for the system to respond to a keypad input after a one or two second delay. This is normal as the heating system performs tests to make sure that everything is in working order before carrying out an operation.

In some cases it takes about five seconds for the system to responds to input commands. This is the case when you reset the system to clear an error code. The system will accept a mode change request after five seconds of lockout, and continue to display the error until you reset it. Afterwards, it goes into last saved mode.

When the error is corrected it will automatically reset and resume operation. You can manually reset the system using the keypad. To reset the system, you should cycle the mode button through ‘STANDBY’ and back to operating mood i.e. ‘Pool’ or ‘SPA’.

Safety Instructions and Operation Info

Electrical Connections

Wiring connections for Hayward H-Series heater should be made by a licensed electrician. The heater must be provided with suitable bonding and grounding. A ground lug is located inside the control panel while a bonding lug is situated towards the side of the heater.

Improper electrical connection can lead to burn, shock, and serious property damage. In order to avoid electrical hazards it is important that the wiring is fully in compliance with national and local codes and regulations. Also, it is important to ensure the correct electrical receptacles are connected.

Gas Connection Checkup

Prior to installing the heater you should make sure that it is purged of all air and filled with water, which will flow through the heater during operation. You must also perform gas line testing to check for gas leaks.

Hayward H-Series Pool & Spa Heater

The water heater including the shutoff valve should be disconnected from the gas supply when testing gas pressure in excess of 3.45 kPA (1/2 psig). Moreover, the gas supply line should be capped if it’s not connected to the heater. You can reconnect the gas piping to the valve once the testing is completed.

Gas pressure should be adequate to ensure the heater functions normally. If there is an improper gas pressure or volume the flame will be totally yellow in color. Also, the heat exchanger can soot up in the case of an irregular gas supply.

To check gas pressure and leaks, you should turn on the gas supply and inspect the entire pipe and tubing joint. Use a solution of water and soap to detect leaks in the pipe. In case the pressure is not adequate, you must check whether the pipe that runs between the heater and the gas meter is of the right size and capacity. The following steps show how you can perform a gas pressure test.

Step 1: Gather the Required Equipment.

You need to obtain the following equipment to check gas pressure running to the heater.

- Manometer

- Screwdriver (flat)

- Pipe nipple (1/8’’ thread and 1’’ long)

- Hex wrench (3/16’’)

Step 2: Remove the plug from the gas valve.

Step 3: Attach a 1/8’’ pipe nipple into the valve.

Step 4: Now, attach the manometer to the pipe nipple.

Step 5: Turn on the heater following the instructions mentioned on the label inside the front access panel.

In case you have installed more than one pool or spa heater that is connected to a single gas supply line, you need to turn on each of the appliances to test the gas pressure.

Step 6: Record the gas pressure reading while the heater is tuned on.

No adjustment is needed in case the pressure is within 1.8’’ to 2.00’’ water column (wc) for natural gas or 6.8’’ to 7.00’’ wc for propane. However, if the gas pressure does not meet these criteria, then you need to perform the following additional steps to adjust the regulator.

Step 7: Remove screw cap from the regulator adjustment screw.

Step 8: Now, turn the regulator clockwise if you want to increase gas pressure and counter clockwise if you need to decrease the pressure.

Step 9: Place screw cap back over the adjustment screw.

When performing the above steps it is important that you avoid replacing the screw cap and it is important that you do no remove the pipe nipple when the valve is turned on. This may create an explosion hazard resulting in serious injury. That’s why it’s extremely important that the valve is turned to off position when removing the nipple for testing gas pressure.

In case a leak is found, you must shut off the gas and call an expert to fix the leak right away. Also, avoid using an open flame to check gas leaks as it can cause an explosion resulting in serious injury or death. Although the gas pressure regulator is preset at the factory for optimal operation, you must still have it checked by the installer to ensure it's functioning as it should.

Once the heater is successfully installed it lights up when it is heating the pool, and shuts down when the water is heated to the required temperature.

Water Pressure Testing

Water pressure is preset at the factory for normal deck level installations. However, adjustments will be needed in case the heater is situated either above or below the pool or spa level. This adjustment is required due to change in static pressure occuring when the heater is positioned at other than deck level position.

The following steps outline how to test and adjust the pressure switch when required.

Step 1: Ensure that the water filter is clean prior to making any adjustments.

Step 2: Next, you must turn on the filter pump.

At this point, you should make sure that all the air is purged out of the water lines. Also, it is important to ensure that the water flow rate is set within the allowable flow rate range that is applicable for the specific heater model.

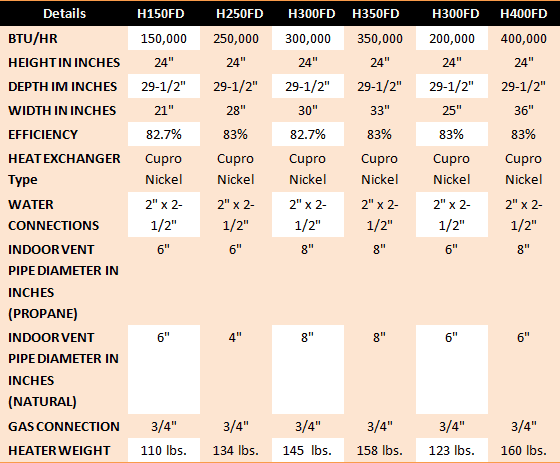

For H150FD and H200FD models, the minimum and maximum allowable range is 20 and 125 gallons per minute (GPM). The allowable minimum and maximum flow rates are 25 and 125 GPM for H250FD and H300 FD models, respectively, while it is 30 and 125 GPM for H350FD and H400FD models. You must never allow the heater to operate if the pressure is below or above these limits.

Step 3: Now, you need to turn on the heater and adjust the thermostat so that the heater light turns on.

You can adjust the pressure by turning the switch in a clockwise or anticlockwise direction. Turning the switch in clockwise direction will increase the pressure, while turning the switch in anti-clockwise direction will decrease the water pressure.

Step 4: Finally, you must check the pressure switch by turning the pump on and off multiple times. The pool heater should turn on instantly when switched on.

Note that in some cases the pressure from a two speed pump will be well below the minimum requirements to operate the heater. You won’t be able to adjust the pressure switch if the pressure is below 1 pound. The only turnaround for this is to run the pump at higher speed. Do not try to operate the heater in case the pressure is below 1 pound minimum requirement.

Temperature Control Procedure

Every Hayward H-series heater is equipped with a temperature control switch. Naturally it adjusts the temperature of the pool or spa water. Using the keypad on the control panel, you can set desired temperature. The control panel also displays temperature and diagnostic information in case of any anomalies.

You can change the temperature to be displayed in either Fahrenheit or Celsius by following the steps below.

Step 1: Place the heater in ‘STANDBY’ by pressing the ‘MODE’ button.

Step 2: Next, hold the ‘MODE’ and ‘STANDBY’ button until the display depicts the °F/°C selection.

Step 3: Now, press the ‘DOWN’ button to toggle between selection.

Step 4: Finally, you must press the ‘MODE’ button to accept the selection. The selection will be automatically selected if you don’t press any button after a minute.

You can set temperature of the heater between 65°F (18°C) and 104°F (40°C). To set the temperature, you must press ‘Up’ or ‘Down’ button while the heater is in ‘Spa’ or ‘Pool’ mode.

Once you set up a desired temperature, the set point will blink for a few seconds on the panel. You can change the temperature by again pressing ‘Up’ or ‘Down’ button as required.

Heating System Problems: Diagnosis and Solutions

In the event the ignition system does not start when a request for heat is made, the system will de-energize the gas valve after 4-seconds and conduct another 30-second purge. At this time the control monitors open connections at the vacuum switch.

Next the system will perform a gas valve relay check, and then again perform an ignition trial. In case the ignition fails to start on the third check, the heating system enters into a safety lockout. It will display the error code ‘IF’ on the screen, and illuminate the ‘Service’ indicator.

The system will rest and clear the error code automatically in case no action is taken by the user after one hour. This cycle will continue until heat is removed or the ignition is developed. A user can also manually reset the error code by pressing ‘Mode’ button, cycle through ‘STANDBY’, and return to the original mode.

In case a flame is established during ignition but then lost again, the system will make up to ten attempts to reignite the flame. If the flame is lost after 10 or more seconds, the system will respond instantly within 0.8 seconds. However, if the flame is lost within 10 seconds, the system will respond within 2 minutes and try to reignite the flame.

The system will de-energize the blower and the gas valve, and check open connections at the vacuum switch. Next, the system performs a gas valve relay check. If the flame fails to ignite after the tenth attempt, it enters into a hard lockout or safety lockout mode after the tenth failed trial, and displays the IF error code and illuminates the ‘SERVICE’ indicator. The control will reset automatically after an hour.

In case a call for request is made at this time, the control will again make three attempts to ignite. In case the flame is not ignited, the system will enter into safety lockout for the second time. However, if the flame is ignited but eliminates after 10 second, the system will make up to 10 attempts to ignite the flame. The cycle will continue until either the heat is removed or an ignition is established.

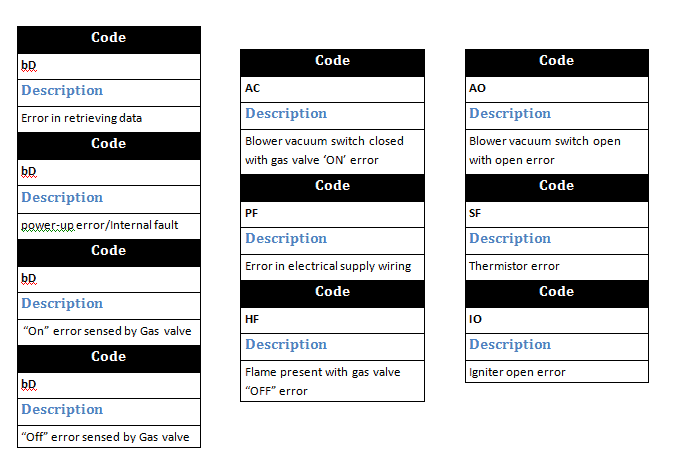

Error Codes and Their Meanings

H-Series heaters will display error codes in case one or more component parts fail to function properly. Here we will take a look at some of the common errors codes and what they imply. Note that some of the codes given below have multiple interpretations that require further investigations to diagnose the real cause of the problem.

Preventive Maintenance and Inspection

These heaters are made to last for a long time. In order to ensure their longevity it is important that you perform periodic checks and maintenance on the system. Regular inspection from a qualified technician will ensure that the heating system continues to function normally for a long time.

Following are the recommended inspections that must be performed at regular intervals.

- Vents should be checked regularly. In the Hayward H Series heaters, the vents are located at the louvered top panel. It’s important that the venting areas should be cleared of any obstructions. This is necessary otherwise it will restrict ventilation and air combustion. Note that sometimes shrubs or trees growing close to your pool side can obstruct the venting area around the pool.

- Indoor heater vents should be checked for possible leaks and looseness. Make sure that all the openings for ventilation and combustion are unobstructed and clear if you are using the heater indoors. The entire pool area must be kept free of any debris, gasoline, combustible materials, and flammable liquids and vapors that could clog the vents.

- Avoid storing chlorine and other corrosive chemicals near the pool heater. In case of the H series propane gas heaters (H150FDP, H200FDP, H250FDP, H350FDP, H400HDP, H500HFP) make sure that the tank does not fall below 30% full otherwise damage to the heater may incur. The warranty will be void in case any defect develops in the heater due to improper levels of gas in the tank.

- When another appliance is added that uses gas to operate, it’s important to make sure that gas line can provide both the units with adequate inputs. Consult the local gas company to install another gas line if it won’t be enough to run the heater.

- In case the water heater accidentally falls in the water, you must disconnect the heater from the electrical outlet and immediately contact a qualified technician. Tell the technician to inspect the heater and replace any part that has damaged due to contact with water.

Regular inspection of the water heater by a qualified technician is an excellent preventive maintenance technique. You must also keep the instruction manual that came with the heater safe so that it can be consulted by the technician during regular inspection.

Hayward heaters will function properly during winter season. However, note that freeze-ups are not covered under warranty so it’s important that you take necessary precautionary steps during frigid winter seasons.

The pump needs to be run continuously during freezing weather. In addition, if the heater is out-of-service all the water must be drained out from the system. This is necessary to avoid damage to piping and heating system due to ice freezing in the water. Draining water from the heat exchanger should be a recommended part of the shutdown during the winter season. Following are steps that should be performed in order to remove water via the drain plug.

Step 1: First of all set the system to ‘STANDBY’ mode by pressing the required keypad input.

Step 2: Next, you must turn off electricity provided to the heater.

Step 3: Now turn off the heater gas valve by turning the knob.

Step 4: Then, you must cut the gas supply to the heater by shutting off the valve that is located outside the cabinet. Also, make sure that the circulating pump is turned off.

Step 5: Finally, remove the drain plug from the header and let the water escape from the heater.

After all water is removed from the heater, you put the drain plug back in place. Performing the above steps will prevent heater freeze-ups when the system is shutdown during winter months. Ice expands when it freezes and can cause severe havoc to your equipment.

Once the winter season ends and the spring season arrives, you must inspect the system and clean the heater if required. Make sure that the heater vents are free of debris, leaves, or any other obstructions before starting up the system.

Next, you should check whether the inlet and outlet pipings are securely attached to the heater and that the drain valve is closed. Then, the filtration system pump should be turned on and the system should be allowed to run long enough so that all the air is purged from the lines. Afterwards, you must turn on the gas supply valve, set the temperature using the keypad to either ‘SPA’ or ‘POOL’, and then finally adjust the settings to set the desired temperature. This routine should be performed every spring season when the heating system is shut off during winter season.

Hayward Heater Annual Inspection

Heaters should be serviced by qualified technicians only, and with appropriate equipment. A user should not attempt to repair the heater as it presents electrical and fire hazards. Moreover, servicing the heater oneself may result in the heater malfunctioning which naturally may result in serious injury or death. You won't need to worry about voiding the warranty there neither.

All the components that are installed in the heater have an effect on the heating performance. That’s why it’s important to ensure that during repairs only company approved parts are used. No attempt should be made to modify the heating components and parts.

Before commencing any repair work, it is important to ensure that the vents, strainers, and filters are not blocked, the timing clocks are properly set, and the piping valves are positioned properly. The following things need to be checked annually to ensure the safe and proper operation of the heater.

Regular Inspection

Check the internal & external heat exchanger every 12 months, and replace if required. The burner flame patterns and main burner orifices should also be checked and replaced if required.

In addition, the operating controls should be checked using the steps outlined below.

- Remove all four screws from the front panel of the control access to reach the operating controls.

- The wires need to be labeled before they are disconnected for servicing the control panel. The technician should consult the wiring diagram in the manual to know how this is done.

- After the service of the control panel is completed, the technician should verify the operation of the panel, and reconnect the wiring.

Note that some of the steps outlined above will require removing and/or disconnecting wires in control compartment.

Cleaning of External Heat Exchanger

The technician should perform the following steps to thoroughly inspect and clean external heat exchanger.

- Turn the main gas valve, pump, and heater power to the off position.

- Disconnect the trim panels at each end of the heater. The panels are secured through four screws that must be removed before commencing services.

- Next, the upper end caps located on both end of the heater should be removed. Again, each cap is secured using four screws that are situated inside the slots at the top and the sides. These need to be removed to pull out the cap.

- Afterwards, the technician has to remove the louvered panel of the external heat exchanger. The panel is secured using three screws located at each end of the top panel and two screws at the back.

- The rain shield that is secured by twelve screws at the top surface of the panel should be removed. Afterwards, flue collector that is located on each side of the panel needs to be removed. There are two screws that secure each panel and which can be accessed from outside the heater.

- Now, remove the access panel in the front of the heat exchange system that is secured by four screws.

- Afterwards, the technician should remove control box cover by removing two screws that secure the box.

- Next the water pressure switch should be disconnected. The switch is located on the water header.

- Then the limit leads that are situated on the underside of water heater need to be disconnected.

- The technician should remove the transistor lead located inside the control box from the ignition control box. This transistor lead should be pulled out of the control box and freed from the chassis of the heater.

- Once all the panels and parts are removed the technician should lift the heat exchanger and place it on a smooth surface for inspection, and cleaning.

When cleaning the heat exchanger, it’s recommended to use a soft brush. Using a wire brush is not recommended to do the cleaning. The technician should use a soft brush to remove soot from the heat exchanger. Using a wire brush poses a fire hazard as the gas trapped within the soot can ignite and spark.

The technician should use a soft tipped brush and apply a degreaser to the external heat exchanger. The degreaser should be applied both at the bottom and top surface of the exchanger. After the degreaser is applied it should be allowed to sit at the top for a few hours until it starts to loosen the soot. Next the heat exchanger should be washed using a garden hose. After the heat exchanger is thoroughly cleaned all the parts should be put back by following the steps mentioned above.

The heat exchanger should be cleaned of soot once a year. Apart from cleaning the soot, it is important to find out the reason why soot had accumulated on the heat exchanger. There are several reasons that soot may start to build up, which must be investigated by the technician. These include:

- Excessive water flow through the heat exchanger

- Inadequate venting,

- Insufficient supply of air

- High or low gas pressure

- Blockage of blower inlet

- Low voltage supply causing the blower to “spin” slower

- Incorrect gas supply pipe size

- LP tank below 30% full

- Blockage of burner tubes or orifices

- Improper heater location installation

Combustion Chamber

The combustion chamber is the piece of casting inside the pool water heater where the heat is produced. This chamber must be checked every year by a qualified service engineer and replaced if required. The steps required to remove and reinstall the combustion chamber is included in the manual that comes with the pool heater.

Heater Burner

Burner inspection and cleaning should also be part of the annual inspection process. The burner produces the flame that heats up the water. In order to clean the burner the following steps should be performed.

- Remove the front access panel while the heater is on. Examine the main burners through the side glass.

- Make sure that the burner flame is about ½’’ to 2’’ in height. In addition, the flame should not lift off the burner ports.

- Also, inspect the color of the flame. The color of the burning flame must be blue. A yellow color indicates restricted air supply. This will result in improper water heating. Another reason for a flame to have a yellow tip is the presence of spider webs in the gas orifices or the burner. Whatever the reason for a yellow flame it will result in inadequate heating of the pool water.

Sometimes the burner will need to be removed either for repairs or replacement. The following steps will allow you to remove the burner from the Hayward water heater.

- Turn off the gas supply, pump, and switch the heater power to the off position.

- Next, turn off the gas valve.

- Now, you must remove the front access panel from the heater. The panel is secured by four screws that must be removed to pull out the access panel.

- Afterwards, the union joint of the gas supply piping located outside the heater cabinet must be disconnected.

- Then, the wring terminals from the gas valve should be disconnected, after which terminals from the blower should be removed.

- The next step is to pull out the gas manifold assembly that is attached to the air box through four screws.

- The igniter access panel should be pulled out after removing the screws. Avoid disconnecting the wires from the igniter.

- Next, the air box cover should be removed. Take care not to remove the blower from the air box cover.

- Finally, remove the screws that secure each burner to the combustion chamber, and then pull the burner straight out of the heater.

After a faulty burner is removed, you must perform the steps below to install a new one in its place.

- Put back screws that secure each burner to the combustion chamber.

- Next, the air box cover should be put back in place.

- Next, the igniter access panel should be placed back and secured by screws.

- The next step is to put back the gas manifold assembly, and attach to the air box through four screws.

- Then, the wring terminals from the gas valve should be connected.

- Afterwards, the union joint of the gas supply piping located outside the heater cabinet must be connected.

- Now, you must put back the front access panel.

The burner must be checked for leaks after it is installed in the heater. You must turn the gas supply on and use a soapy solution to detect any leaks. If bubbles form on the supply pipe, it indicates a leak. If a leak is detected you should have the gas supply pipe repaired by a qualified technician.

Remember that you must not use an open flame to check for leaks.

Heater Gas Valve

Heater gas valves should also be examined annually. Make sure that the valve is functioning properly allowing the heater to produce the flame and heat the water. In case the heater is not able to heat the water, it needs to be replaced by following the steps outlined below.

- Turn off the gas supply, pump, and the heater power.

- Next, disconnect the union joint in the gas supply piping.

- Remove screws that secure the front panel.

- Now, disconnect the wiring terminals from the gas valve.

- Remove the screws that secure the gas manifold assembly.

- Afterwards, unscrew the gas valve, and remove the elbows from the valve.

- Finally, reassemble the gas manifold assembly using the new gas valve. It is important to consult the manual to find out the correct orientation of pipe elbows, manifold pipe, and the gas valve.

Note that you must use liquid pipe dope on the gas manifold pipe and the male threads of the elbow. It’s important to avoid placing the dope pipe on the threads of any joint.

Igniter Inspection

The igniter is an important component of any gas heater that must be checked annually. Check the igniter to ensure that it is providing the adequate amount of heat required to heat the water to a specific temperature. In case the igniter needs to be replaced you should perform the steps that are outlined below.

- Turn of the gas supply, pump, and power.

- Remove the screws that hold the front access panel.

- Next, you must remove the control box cover that is secured with two screws.

- Afterwards, you must disconnect the igniter wires from the ignition control board.

- The next step is to pull the igniter wires from the control box. There is an opening in the bottom through which you can disconnect the igniter.

- Then, the screws that secure the igniter access panel should be removed.

- Next, press the bushing out of the hole located in the sheet metal panel while working from the underside of the panel.

- Then, the igniter wires must be pulled through the slot on the panel, and pull out the panel.

- Next, you must pull the faulty igniter straight back and out of the air box.

Replace the faulty igniter and reassemble the unit by performing the above steps in reverse order.

Flame Sensor

The flame sensor needs to checked every year to ensure that it working properly. In case of any problems the steps outlined below should be performed to replace the flame sensor.

- Turn the gas supply, pump, and heater to the off position.

- Remove the front access panel.

- Remove all wires from the flame sensor.

- Pull out the sensor after removing the screws that holds it in place.

- Finally, replace the flame sensor by performing the above steps in reverse order.

Burner Orifices

The burner orifices need to be replaced whenever they fail to properly heat the system. The below steps outline how to remove orifices from the heater.

- Turn off the gas supply, pump, and heater power.

- Now, remove the union joint in the piping of the glass supply outside the heater cabinet.

- Remove the screws that secure the front access panel.

- Next, disconnect all terminals from the gas valve.

- Afterwards, you must remove the gas manifold assembly. This assembly is secured using four screws.

- At last, the orifice should be removed with a 7/16’’ wrench.

- Place a new orifice into the gas manifold pipe without over tightening or cross threading as it will result in a leak.

Blower Vacuum Switch

The blower vacuum switch must also be inspected during an annual review. If any defect is found it needs to be repaired or replaced. The following steps outline how a blower vacuum switch is removed from the heater.

- Turn off the gas supply, pump, and heater power.

- Now remove the screws that hold together front access panel.

- Afterwards the wiring of the pressure switch should be removed.

- Next, pull the tubing from the house barb, and remove screws that hold the pressure switch.

- At last, the pressure switch should be installed, and the above steps repeated in reverse order to complete the procedure.

High Limit Switches

High limit switches are important components of a heating device that need to be checked annually to ensure that the heater performs efficiently. The switch is an automatic resetting safety device that is wired in series with gas and thermostat valves. Hayward H-Series heater feature two high limit switches that are situated on the water header underneath the outlet connection. Both the limit switches are interchangeable as they have the same temperature settings.

If the temperature of the water goes above an expected temperature, the heater will close the gas supply to the burner by closing the gas valve. A fluctuating high limit operation is indicative of a problem. This problem may be caused due one or more of the following reasons.

- Excessive water flow through an external bypass if it is used

- Clogged Strainer or Filter

- Excessive flow through an external bypass

- Accumulation of lime scale in the heat exchanger

- Faulty High Limit Switch

Each of the above problems needs to be addressed to solve the problem. If the issue is caused by a faulty high limit switch, then the following procedure should be followed to repair or replace the switch.

- Turn off the gas supply, pump, and power supplied to the heater.

- Next, drain the heat exchanger of all water.

- Now, you must drain water from the heat exchanger.

- Remove the high limit wires from the harness, and unscrew high limit switch.

- Replace or repair the high limit switch as required.

Note that before reinstalling the high limit switch, you will need to use new sealant. Once a sealant is applied to the switch, you must reassemble the system by following the above steps in reverse order.

Thermistor

Hayward H-Series heaters feature a thermistor that measures water temperature. Ask the technician to check whether the thermistor is functioning properly. In case it needs to replaced, the following steps need to be performed.

- Turn off the gas supply, pump, and power supplied to the heater.

- Afterwards, drain water from the heat exchanger.

- Next remove front access panel after removing the four screws that hold the panel.

- Afterwards, the control box cover needs to be removed. This is secured with two screws.

- Now, pull out the thermistor connector from the control board.

- Remove thermistor leads from outside the heater by pulling it out of the control box, and then through the hole in the chassis.

- Then you need to unscrew the thermistor from the inlet side of the header.

- Finally, replace the faulty sealant with a new one.

Just like when installing a high limit switch, a new sealant should be applied to the thermistor. This is important to avoid the water from permeating and damaging the device. After the thermistor is installed, the above steps need to be performed in reverse order to complete the procedure.

Water Pressure Switch

A water pressure switch is another component of the Hayward H-Series that should be inspected annually. This switch is set at the factory for deck level installations. Adjustments of the water switch are required in case the heater is installed below the level of the pool or spa. This adjustment is required to make allowance for no-flow static head.

The following steps outline how to adjust and replace a water pressure switch when required.

- Before making any adjustments, make sure that the water heater filter is clean.

- Set the water heater to either ‘SPA’ or ‘POOL’ mode.

- Now turn the adjustment dial in clockwise direction until you hear a click from the gas valve.

- Next, you must turn the adjustment dial counterclockwise about ¼ turn/.

- Turn the pump on and off multiple times.

The heater should turn off instantly after the pump is shut off. In case the heater does not turn down with the pump, you need to repeat the above steps until the switch is adjusted properly. Never operate the pool heater without first properly adjusting the water pressure switch.

To replace the pressure switch, a qualified technician should perform the steps that are outlined below.

- Turn off the gas supply, pump, and power supplied to the heater.

- Remove the terminals from the limit switch from the main harness.

- Now, you must remove screws that secure the metal pane.

- Next, wires should be removed from the switch.

- Afterwards, you must use a two ½’’ open end wrench to remove pressure switch from the tubing.

- Finally, you should replace a faulty pressure switch with a new one.

Before reinstalling the switch it is important to apply sealant on the switch. The above steps should be completed in reverse order to complete the procedure of replacing the water pressure switch.

Transformer

Annual engineering inspections should also include the heaters transformer. A transformer converts supply voltages (either 120 VAC or 240 VAC) to a 120 VAC output for the ignite and blower power, and 240 VAC for control circuits, the ignition control board, or the gas valve.

The following steps outline steps what must be performed to replace a faulty transformer.

- Turn off the gas supply, pump, and heater power.

- Next, remove the front access panel that is secured by four screws.

- Afterwards, remove the control box cover that is secured with two screws.

- Now, remove the wires from the transformer leads, and remove the transformer from the control box by removing it's holding screws.

- Replace the faulty transformer with a new one and repeat the above steps in reverse order to complete the procedure.

Heater Blower

An important component of the heater that must be part of the annual check is the heater blower. A heater blower provides air that mixes with the gas at the burners. This helps in the combustion process thereby properly heating the water.

The blower operates at multiple levels during the heating process. It operates during the pre-purge period, during the time the gas valve is open and about 30 seconds after a heating cycle is completed. This component should be checked annually by a qualified technician. The following steps should be performed in case the blower needs replacement.

- Turn off the gas supply, pump and heater power.

- Remove the screws from the front access panel and control box cover.

- Disconnect the blower wire from the control board.

- Pull tubing from the hose barb, and remove the air inlet screen from the blower.

- Remove the blower from air box cover after taking out the screws.

- Lastly, you must place the new blower in place of the defective one.

Make sure that the blower outlet gasket is in the proper position before reassembling the system. Follow the above steps in reverse order to reassemble the system and complete the procedure.

ByPASS Service Cartridge

The ByPASS Service cartridge if installed must be checked annually to ensure it's proper operation. The valve flaps of the cartridge must rotate smoothly on the shaft. Moreover, the spring should fully close the valve. The following steps should be performed if the cartridge requires replacement or repair.

- Turn off the gas supply, pump and heater power.

- Fully drain the water from the Hayward heat exchanger.

- Next, remove all screws that hold the plastic heater side panel to access the header.

- Afterwards, remove the retaining nut from end of the header.

- Next, apply silicone o-ring grease on the seals on the new bypass cartridge. The silicone should be Hayward Jack’s 327 Multilube P/N SP032712, or equivalent).

- Next insert the bypass cartridge in the header with an arrow on the end of the cartridge pointed in an upwards direction.

Before reassembling the unit it is important to check that the flaps are working properly, and the spring fully closes the valve. Also, do not over tighten when installing the nuts otherwise it may damage the bypass cartridge. It’s recommended to tighten the nuts by using the hands.

Heater Wiring

Heater wiring should be inspected annually. Make sure that wiring is properly insulated, and replace or apply electric tape if required. Also, the heater wiring should be inspected for damage. The wiring can get damaged due to short circuits or overvoltage. Get the wiring replaced by the technician in case it is damaged.

Fuse Specifications

Fuse specifications inf Hayward H-Series heaters are printed on the control board and the ignition board. Fuses can be purchased from Hayward in the form of a service parts kit or from a local hardware store. The following are fuse specifications of the H-Series.

- Transformer primary (FC1 & FC2 fuse) - 3A slo-blo fuse; type C520 or 2AG.

- Low voltage (F1 fuse) - 3A blade style fast-acting automotive fuse; type 257.

- Transformer secondary (FC3 fuse) - 1.5A slo-blo; type C520 or 2AG.

- Transformer secondary (FC4 fuse) -2.5A slo-blo; type C520 or 2AG.

How to Convert Gas Sources in Hayward H-Series Heaters

Note that it is possible to covert factory installed gas trains if required from propane to natural gas and from natural gas to propane. This is made possible using conversion kits that are available from the factory.

The gas conversion kit should be installed by a qualified and expert service agency. For detailed instructions you must consult the manual that comes with the kit.

Buying Options

Full Range Available at PoolCenter.com

H200FDN - 200k BTU - Electric/Natural Gas

H200FDN - 200k BTU - Electric/Natural Gas H200FDP - 200k BTU - Electric/Propane

H200FDP - 200k BTU - Electric/Propane H250FDN - 250k BTU - Electric/Natural Gas

H250FDN - 250k BTU - Electric/Natural Gas H250FDP - 250k BTU - Electric/Propane

H250FDP - 250k BTU - Electric/Propane H350FDN - 350k BTU - Electric/Natural Gas

H350FDN - 350k BTU - Electric/Natural Gas H350FDP - 350k BTU - Electric/Propane

H350FDP - 350k BTU - Electric/Propane H400FDN - 400k BTU - Electric/Natural Gas

H400FDN - 400k BTU - Electric/Natural Gas H400FDP - 400k BTU - Electric/Propane

H400FDP - 400k BTU - Electric/Propane H500FDN - 500k BTU - Electric/Natural Gas

H500FDN - 500k BTU - Electric/Natural Gas H500FDP - 500k BTU - Electric/Propane

H500FDP - 500k BTU - Electric/Propane